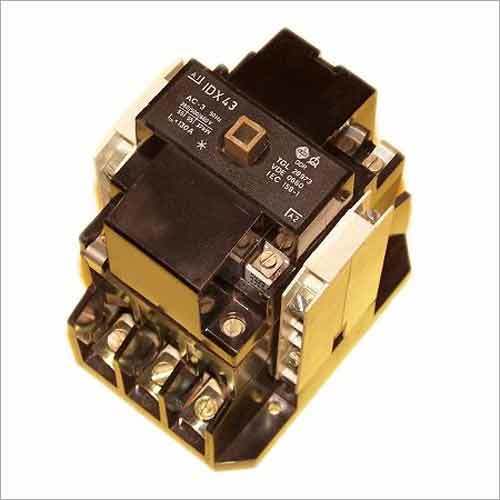

Clutches for Hydraulic Pumps

Product Details:

X

Product Description

Clutches for hydraulic pumps are mechanical devices used to engage and disengage the power transmission between the engine and hydraulic pump in mobile machinery and industrial equipment. These clutches play a crucial role in controlling the hydraulic system, allowing for efficient power management and improved vehicle or machine operation.

FAQs:

Q: What are Clutches for Hydraulic Pumps?

A: Clutches for hydraulic pumps are specialized mechanisms designed to connect or disconnect the hydraulic pump from the engine's power source. They enable operators to control the flow of hydraulic fluid and regulate the power delivered to hydraulic systems, optimizing performance and energy consumption.

Q: How do Clutches for Hydraulic Pumps work?

A: Hydraulic pump clutches work by employing friction plates or electromagnetic coils to engage or disengage the pump's connection to the engine's power. When the clutch is engaged, power is transmitted, allowing the pump to operate and generate hydraulic pressure. Disengaging the clutch stops the pump, interrupting hydraulic flow.

Q: Where are Clutches for Hydraulic Pumps used?

A: Clutches for hydraulic pumps are commonly used in various applications, such as mobile machinery (excavators, loaders, tractors), industrial equipment (cranes, forklifts), and hydraulic power units. They are essential in machines where precise control of hydraulic power is necessary.

Q: What are the types of Clutches for Hydraulic Pumps?

A: There are different types of hydraulic pump clutches, including mechanical clutches, which use friction surfaces to engage and disengage the pump, and electromagnetic clutches, which utilize magnetic fields for activation. The choice of clutch type depends on the specific application and control requirements.

Enter Buying Requirement Details

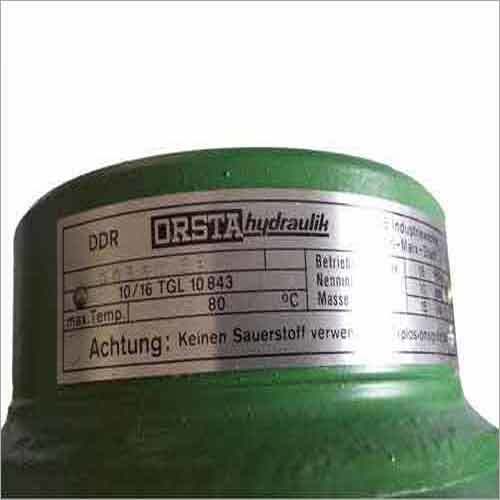

Other Products in 'Orsta Hydraulic Products' category

We are dealing only in bulk order quantity.

|

FIRMA HANDLOWA LENART

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry